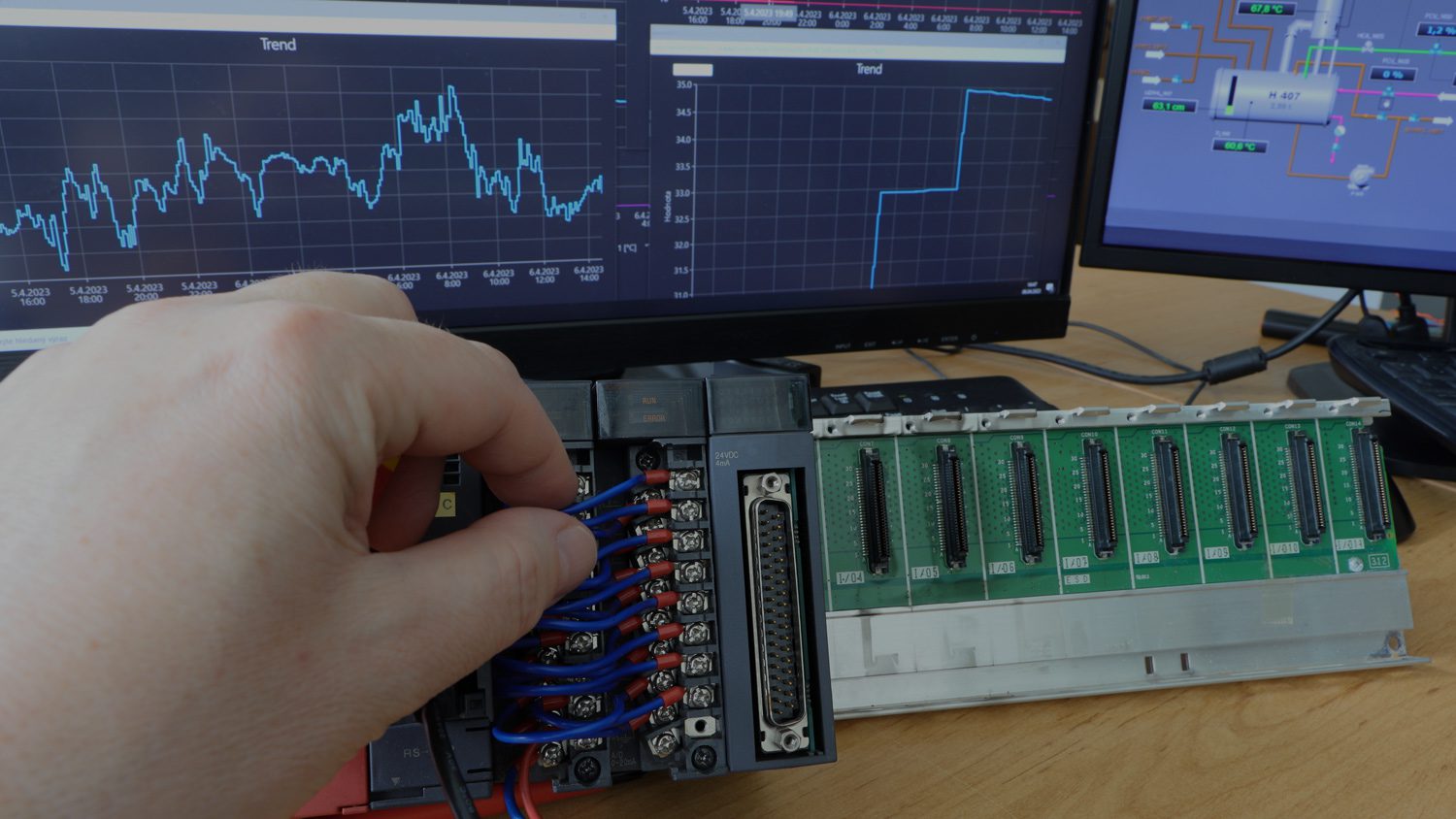

The client is a prominent market leader in Europe, specializing in the design and provision of high-quality emission control systems for passenger cars, including fabricated insulated manifolds and catalytic converters. With an extensive workforce comprising over 6500 skilled employees, the client operates more than 30 manufacturing companies and 16 distribution centers across the globe, catering to the needs of major car manufacturers worldwide. The company has garnered a formidable reputation for its top-of-the-line products and services and continues to remain at the forefront of the automotive industry, thanks to its unwavering commitment to quality and innovation. The program entails designing and developing a new exhaust system for the customer’s modular car platform. One of the key challenges was to ensure that the exhaust systems could be uniformly positioned across different car models to minimize engineering costs, weight, and complexity during the porting process. The team also aimed to develop a standardized, interchangeable set of parts that could be used to build a range of cars, resulting in a 30% reduction in the time taken to build a car. TAAL Tech’s interventions enabled the client in implementing weight reduction and alternative materials initiatives, thus resulting in an overall reduction in manufacturing costs for the exhaust system. The use of a modular concept design and standardization across customers’ car platforms further contributed to cost-effectiveness. The modular design of the welding fixture also significantly reduced the changeover time by 40% when welding two different modular exhaust systems, resulting in improved efficiency. About Our Client

Business Challenges

Results Delivered

Want to learn more about this engagement?

Download the full case study