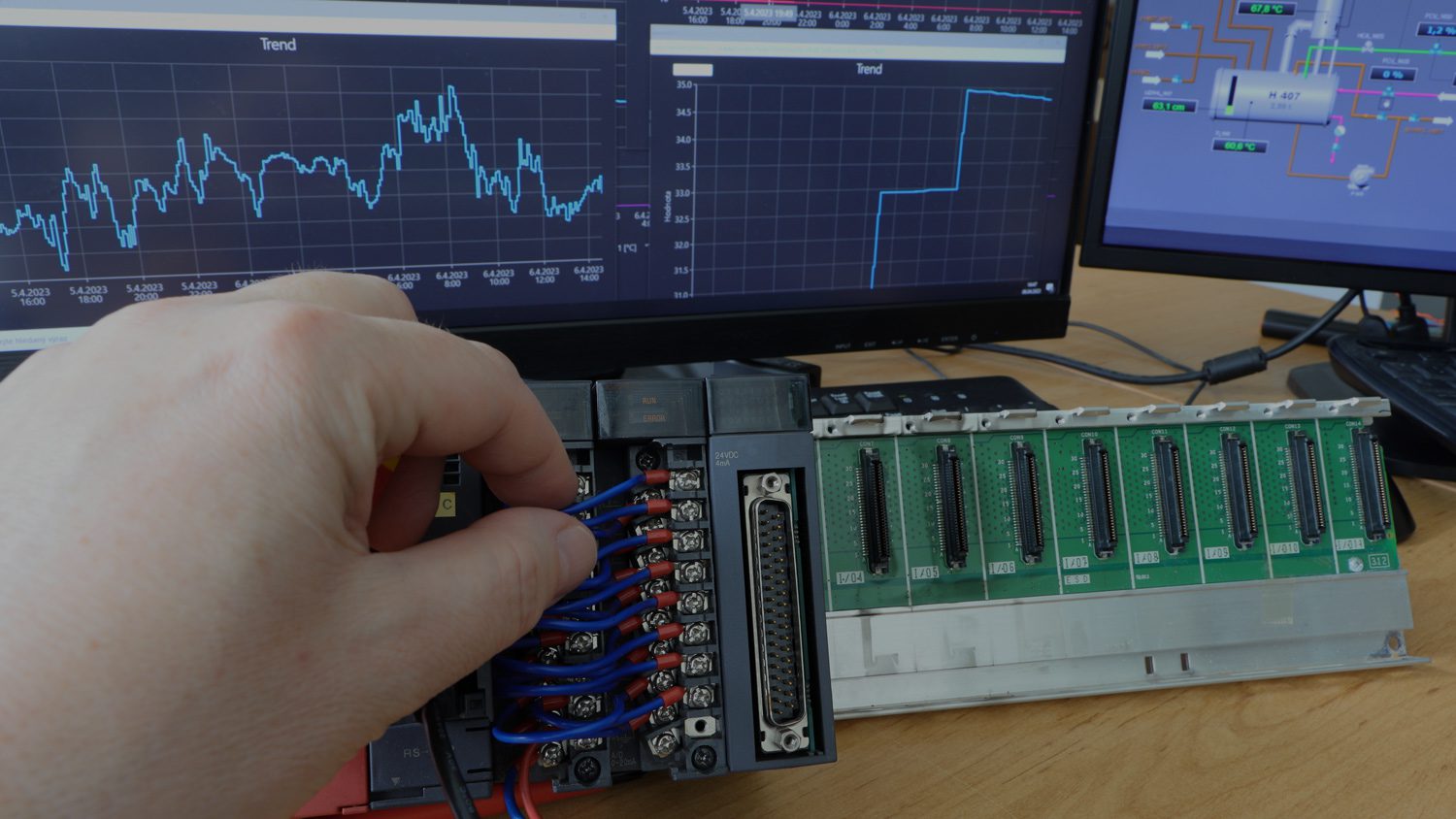

Our client manufactures mechatronic, electronic and electrical products and supply a variety of hydraulic cylinders, hydraulic systems and hydraulic components as well as condition monitoring systems, etc. They have over 20 different products which are marketed across various European industrial companies. With over 700 employees already, they are now venturing into the areas of vehicle technology and special vehicle construction as well as technical building equipment. The requirement of our client was a PLC based application specifically developed with Beckhoff TWINCat, which can be used to build class libraries by our offshore PLC developers. HMI user screens were also within scope of the development. These class libraries were used to enhance the existing functionality available within the TWINCat and provide to end users of our client to operate industrial machinery. Several other features like dashboard monitoring, displaying status of different process areas, changing control parameters, integrating with a central CRM system were also part of the scope. The main challenges faced during this project include lack of expertise available with TWINCat product since it’s new in the market and it is quite different from other traditional PLC development tools. The developers had to attend several trainings over the years from Beckhoff to meet all the technical needs of the customer. Furthermore, there was not much online help on technical issues, and developers had to find some way of resolving technical development issues they would get stuck at. TAAL Tech Development Team was able to develop 5 libraries that can be easily imported to our client’s end users’ systems and get the full HMI experience developed from our offshore office. This saved a lot of time for our client to make custom modifications from their end every time. The data received from PLC was integrated into the customer’s CRM system which helped them receive vital data about their machinery which they utilized for predictive maintenance of their machinery. About Our Client

Business Challenges

Results Delivered

Want to learn more about this engagement?

Download the full case study