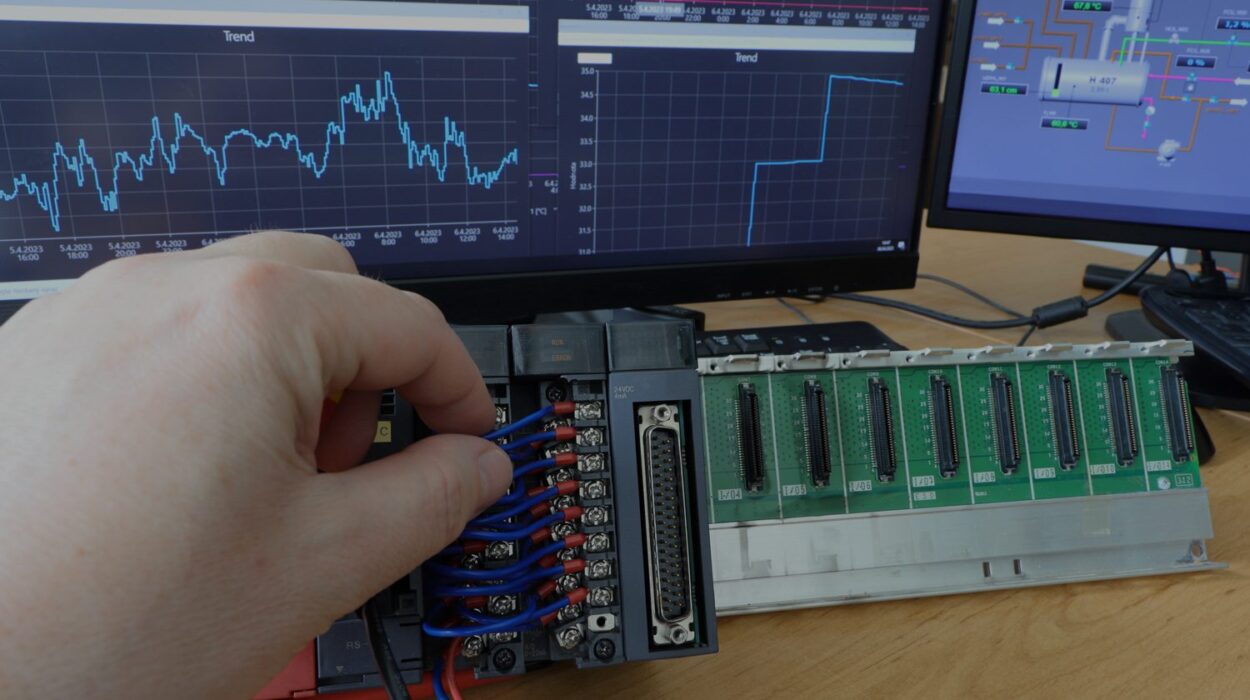

Manufacturing today isn’t just about churning out products; it’s about integrating technology to optimize processes, maximize efficiency, and achieve unprecedented precision. Remote Device Management for Manufacturing involves overseeing and controlling industrial devices and equipment from a centralized location. This service allows for monitoring, maintenance, and troubleshooting without physical presence, enhancing efficiency, and reducing downtime. It enables manufacturers to remotely configure, update, and manage a network of devices, ensuring optimal performance. With real-time insights and control, this technology contributes to predictive maintenance, minimizing disruptions and maximizing productivity in manufacturing processes. Remote Device Management is a crucial component of Industry 4.0, transforming traditional manufacturing by integrating digital technologies for streamlined and responsive operations. At TAAL Tech, we understand the unique challenges of the manufacturing sector and offer specialized Remote Device Management solutions tailored to its intricacies. Centralized Device Monitoring services involve the remote oversight of various devices and systems from a centralized location. This enables real-time monitoring, analysis, and management of connected devices across networks. The service provides a comprehensive view of device performance, facilitating proactive issue resolution and optimizing operational efficiency. Whether in IT infrastructure, manufacturing, or IoT ecosystems, centralized monitoring enhances visibility, minimizes downtime, and allows for swift response to potential issues. It plays a vital role in maintaining the health and functionality of interconnected devices, ensuring seamless and reliable operations in diverse industries. A comprehensive platform displaying the status, performance, and health of every connected device across the facility. Swiftly detect anomalies or breakdowns, reducing downtimes and losses. Regularly monitor wear and tear and anticipate maintenance needs before breakdowns occur. Remote Configuration & Control services empower users to manage and adjust device settings from a centralized location, regardless of physical proximity. This technology facilitates efficient and timely modifications to devices, enhancing flexibility and responsiveness. Whether applied in IT networks, industrial systems, or IoT environments, remote configuration and control services streamline operations, reduce manual intervention, and contribute to overall system optimization and adaptability. Seamlessly push software and firmware updates to devices, ensuring they remain updated and secure. Remotely adjust device settings to cater to changing production requirements or to optimize performance. Take remote control in emergencies, ensuring the safety of assets and personnel. Security & Compliance services are critical for safeguarding sensitive data and ensuring adherence to industry regulations. These services encompass a range of measures, including risk assessments, cybersecurity audits, and the implementation of robust security protocols. By staying abreast of compliance requirements, organizations can mitigate risks, protect against cyber threats, and uphold data privacy standards. Security & Compliance services play a pivotal role in building trust with stakeholders, avoiding legal repercussions, and fostering a secure operational environment in an ever-evolving landscape of cybersecurity challenges. Protect data transmissions between devices and the central system, ensuring data integrity and security. Check devices for adherence to industry regulations and standards, maintaining a compliant production environment. Real-time monitoring for unauthorized access attempts, safeguarding the integrity of the manufacturing process. Predictive maintenance is a proactive approach that uses data analytics and machine learning to predict equipment failures before they occur. By analyzing historical and real-time data from machinery, organizations can anticipate potential issues, schedule maintenance activities strategically, and minimize downtime. This data-driven strategy not only reduces maintenance costs but also enhances equipment reliability and extends its lifespan. Predictive maintenance is a key component of Industry 4.0, transforming traditional maintenance practices into a more efficient and cost-effective process for various industries, from manufacturing to transportation. Utilize historical and real-time data to predict equipment failure or maintenance needs. Receive timely alerts about upcoming maintenance requirements, ensuring devices are always in top operational form. Plan and allocate resources for maintenance based on predictive insights, ensuring minimal disruption to production. Integration and scalability services focus on seamlessly incorporating diverse systems and ensuring a framework’s ability to expand with growing demands. These services involve connecting disparate technologies, optimizing data flow, and enabling interoperability. The goal is to create a cohesive ecosystem that can adapt to changing requirements and scale efficiently. Whether in software development, cloud infrastructure, or enterprise solutions, integration and scalability services enhance flexibility, improve system performance, and future-proof businesses, allowing them to evolve and meet the evolving needs of the digital landscape. Ensure seamless integration with various manufacturing devices and platforms. Easily add new devices to the system without overhauls, catering to the evolving needs of the manufacturing floor. Connect with other enterprise systems like ERP, SCM, and MES for a holistic manufacturing management solution. Streamlining operations in a dynamic industrial landscape

Centralized Device Monitoring

Unified Dashboard

Real-time Diagnostics

Device Health Metrics

Remote Configuration & Control

Services

Over-the-Air Updates

Parameter Tuning

Shutdown & Restart

Security & Compliance

Services

Encryption & Authentication

Regular Audits

Intrusion Detection

Predictive Maintenance

Services

Data Analytics

Maintenance Alerts

Resource Allocation

Integration & Scalability

Services

Cross-platform Compatibility

Modular Architecture

API Integrations

Our Credentials

Why TAAL Tech?

Secure better project outcomes & improved ROI with TAAL Tech’s digitized engineering support. Get started now!

10+

Industries

150+

Clients

16+

Years

700+

Employees

This website uses cookies to improve your web experience.