Role of Manufacturing Design Engineers in Modern Product Development

In modern industry, time-to-market, cost pressure, and rising quality expectations are all peaking at once. In this environment, manufacturing design engineers sit at the center of product success. They bridge the gap between what customers want, what marketing promises, what R&D imagines, and what factories can reliably produce at scale.

Their decisions on geometry, materials, tolerances, and processes influence performance, manufacturability, sustainability, and total lifecycle cost far more than any downstream optimization.

From Requirements to Manufacturable Concepts

The role of design engineers in product development starts long before the first 3D model is approved. They translate vague market requirements into clear engineering specifications: loads, environments, safety factors, service life, regulatory constraints, and cost targets.

Product design and development engineers then generate concepts that can meet these needs while still fitting into real-world industrial capabilities—available materials, standard parts, machine envelopes, tooling constraints, and supplier capabilities. Good manufacturing engineering design avoids “heroic” solutions that are elegant on screen but impossible or uneconomical on the shop floor.

Design for Manufacturing, Assembly, and Cost

Mechanical design engineering for manufacturing is increasingly defined by “design for X” disciplines—design for manufacturing (DFM), design for assembly (DFA), design for cost (DFC), and design for service (DFS).

Manufacturing design engineers systematically reduce part counts, eliminate unnecessary features, and standardize components to simplify assembly and reduce handling. Even small changes—switching from custom fasteners to standard ones, adjusting wall thickness to suit molding or casting, or redesigning a bracket for a simpler bend sequence—can unlock major cost savings across thousands of units. Their work is where engineering creativity directly converts into margin protection.

Industrial Product Design Engineers and Cross-Functional Collaboration

Industrial product design engineers do not work in isolation from operations. They interact closely with process engineers, quality teams, supply chain, and production supervisors to refine the industrial design and manufacturing workflow.

Design reviews increasingly include representatives from machining, fabrication, welding, injection molding, or PCB assembly, depending on the product. This collaborative approach allows issues such as tool access, fixturing, inspection strategy, and ergonomics to be addressed during the design phase instead of on the shop floor, where changes are slower and more expensive.

Rapid Prototyping and Digital Validation

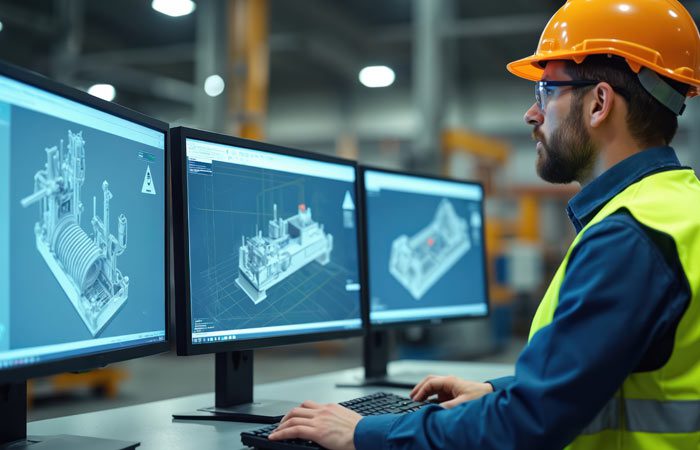

Modern rapid prototyping and product design engineering workflows give manufacturing design engineers powerful levers to reduce development risk. Using 3D printing, soft tooling, and quick-turn machining, they can test ergonomics, assembly sequence, and critical interfaces early.

At the same time, simulation tools—structural FEA, CFD, mold flow, topology optimization, and tolerance analysis—allow them to explore dozens of options virtually before cutting any steel. This blend of virtual and physical prototypes helps converge faster on designs that are both robust in the field and stable in production, shortening development cycles while maintaining quality.

Digital Threads and Integrated Toolchains

Mechanical and manufacturing engineering solutions today are built on integrated digital toolchains. CAD models feed directly into PLM systems, where bills of materials, change histories, and requirements are controlled. From there, data flows into CAM for toolpath generation, into CMM programming for inspection, and into MES systems for production tracking.

Manufacturing design engineers are responsible for ensuring that product and process data stay synchronized across this digital thread. A small change in a 3D feature can cascade into new cutting tools, gauging strategies, assembly instructions, and even packaging design—so robust configuration and change management is critical.

Scaling from Prototype to Mass Production

Many good prototypes fail at industrialization because they were never truly designed for scaled production. This is where manufacturing design engineers are indispensable. They adapt designs for different volume regimes—low-volume customization, mid-volume flexible cells, or high-volume dedicated lines.

They make decisions on process selection (machining vs casting vs additive), part family strategies, modularization, and platform reuse. In globalized supply chains, they also consider logistics, regional standards, and supplier capability differences when finalizing designs. Their work at this stage determines how smoothly ramp-up proceeds and how quickly yield, scrap, and cycle times stabilize.

Why Companies Turn to Outsourced Engineering Design Services

As products become more complex—mechatronics, embedded electronics, connectivity, and regulatory requirements—many organizations cannot build all capabilities in-house. Outsourced engineering design services allow OEMs and industrial firms to access specialized skills in areas like lightweighting, NVH, thermal management, or complex surface modeling, without locking in permanent headcount.

Product engineering consultancy services can also provide standardized frameworks, templates, and best practices drawn from multiple industries. This is especially valuable for mid-sized manufacturers who need world-class engineering but must stay lean and cost-competitive.

Partnering for End-to-End Product Development Engineering Services

The best partners for product development engineering services are those who can connect design intent with manufacturing reality—across concept, detailed design, prototyping, process planning, and ramp-up. They combine industrial design and manufacturing workflow expertise with practical knowledge of machining, forming, molding, joining, and automation.

An organization like TAAL Tech, for example, can support OEMs with outsourced engineering design services that span multi-CAD environments, CAE-driven optimization, DFM/DFA, and production-ready detailing, acting as an extension of the customer’s internal team rather than a transactional vendor.

Design Engineers as Value Multipliers

In modern product development, manufacturing design engineers are not just “drawing creators.” They are value multipliers who shape performance, cost, quality, and sustainability from the earliest stages of development. By integrating customer requirements, advanced simulation, rapid prototyping, and factory realities into one coherent approach, they ensure that products can be built reliably, repeatedly, and profitably.

For organizations seeking mechanical and manufacturing engineering solutions—whether in-house or through strategic partners—the real differentiator is how effectively manufacturing design engineers are empowered and integrated into the entire product lifecycle.