Lightweight Trailer Chassis: A Game Changer in Transport Design

When you’re moving goods across cities, states, or continents, every kilo counts. Whether you’re managing a logistics fleet or designing trailers for tomorrow’s transport systems, the pressure is on—to cut fuel costs, reduce emissions, and carry more with less. That’s exactly why the lightweight trailer chassis is turning heads across the industry.

It’s not just a design tweak—it’s a fundamental shift in how trailers are built and how fleets perform. Lighter, smarter, and engineered for the real world, these new-age chassis are helping companies rethink everything from fuel-efficient trailer design to long-term cost savings. And as demand for leaner, greener transportation grows, so does the need for smart engineering and stronger materials.

The Weight of Fuel Costs

Here’s the thing: fuel efficiency and trailer weight go hand in hand. The heavier the trailer, the more fuel it takes to move. It’s a simple equation with big consequences for fleet operators. But with fuel savings from lightweight trailer frames ranging from 5–15%, even modest reductions in chassis weight can make a big impact on the bottom line—especially when scaled across a large fleet.

Beyond fuel, lighter trailers also wear down tires more slowly, reduce stress on braking systems, and improve maneuverability on the road. It’s not just about efficiency—it’s about giving drivers and operators a better, safer experience.

Building Better with Stronger, Lighter Materials

One of the biggest enablers of this trend is the growing use of high-strength materials for trailers. Traditional steel is strong but heavy, while aluminum is light but sometimes struggles with durability. The “Aluminum vs steel trailer chassis” debate has driven a lot of innovation in modern trailer manufacturing, and the industry has responded with hybrid designs, reinforced structures, and even next-gen solutions using composite materials for trailers.

These new materials offer better strength-to-weight ratios and resist corrosion—making them ideal for long-haul conditions. The smart use of composite materials or lightweight aluminum also plays a big role in long-term cost savings through better lifecycle performance.

Smarter Design, Smarter Logistics

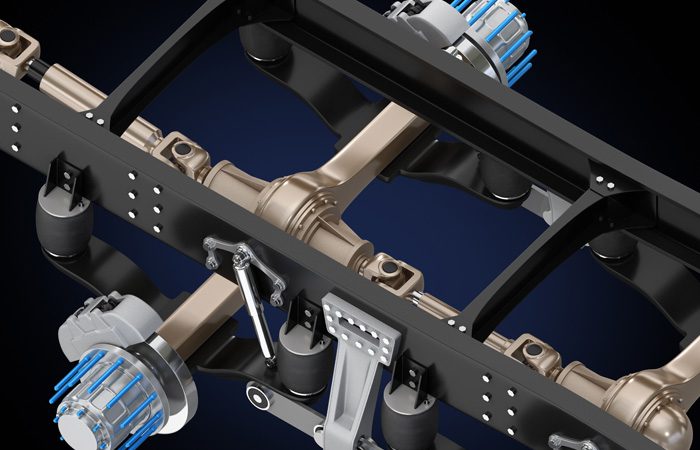

Material selection is only part of the story. The magic really happens during the lightweight trailer chassis design process. Today’s engineers use simulation software, digital twins, and FEA tools to test designs long before they hit the shop floor. The goal? Trailer chassis optimization that maintains structural strength while shedding unnecessary weight.

This kind of structural trailer design is critical for maintaining safety and compliance without sacrificing performance. Whether you’re designing a chassis for refrigerated goods, construction equipment, or dry freight, the structure must be both lightweight and robust. It’s a tricky balance—but one that today’s tools and talent are well-equipped to handle.

Tackling Design Challenges with Innovation

Of course, there are real design challenges in lightweight trailer engineering. For one, lighter materials can behave differently under stress. There’s more flexibility to account for, and higher risks of fatigue or failure if the design isn’t thoroughly tested. Engineers must also factor in the rigors of real-world logistics—uneven roads, shifting loads, and harsh weather.

That’s where techniques like modular framing, reinforced joint design, and load distribution modeling come in. The challenge is maintaining the structural integrity of lightweight trailers without making the design overly complex or expensive. It’s not easy—but the payoff is well worth it.

The Bigger Picture: Performance + Sustainability

Let’s zoom out for a second. What does all this mean for logistics and transport companies?

Quite a lot, actually.

Lighter trailers mean fleet efficiency improvements. More payload can be carried without exceeding weight limits. Trips can be optimized. Fewer trips may be needed for the same volume of goods. And, crucially, carbon emissions go down—making it easier for companies to hit their sustainability goals.

The benefits of lightweight trailer chassis in logistics aren’t just technical—they’re strategic. And in a world where cost, compliance, and climate action matter more than ever, a lighter fleet gives companies an edge.

A Real-World Approach to Lightweight Logistics

Companies like TAAL Tech are already working with global trailer manufacturers to push the boundaries of weight reduction in trailer engineering. With a mix of structural design expertise, material science insight, and manufacturing know-how, they help clients develop durable, compliant, and scalable lightweight chassis for cargo trailers.

Their approach combines advanced CAD/CAE tools, simulation, and validation to ensure every gram saved translates into real-world gains in fuel, safety, and performance.

Moving Transport Design Forward

The transportation industry isn’t just moving freight anymore—it’s moving toward smarter, cleaner, and more efficient ways of doing business. And the lightweight trailer chassis is a key part of that transformation.

From smarter material choices to better design practices, this innovation is helping fleet operators unlock real advantages—on the road, in the shop, and at the pump.

Whether you’re looking to improve fuel-efficient trailer design, explore trailer chassis optimization, or simply future-proof your logistics strategy, one thing’s for sure: lightweight is no longer a luxury. It’s the new standard.