Design to Delivery — Automotive Concept & Detailed Engineering

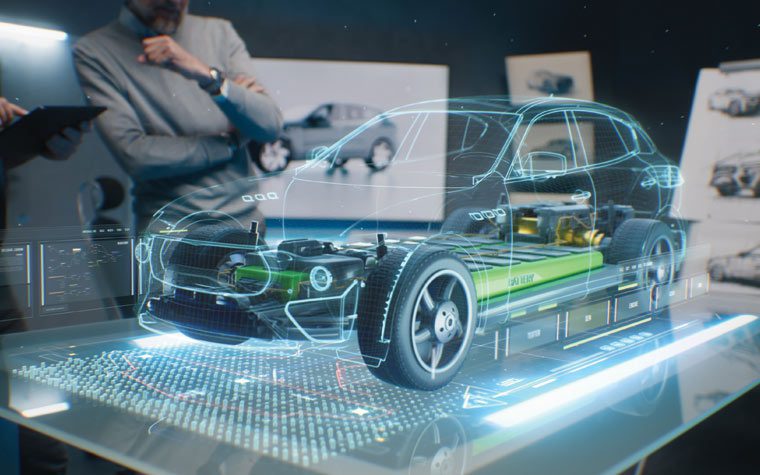

Designing a vehicle is more than sketching ideas and adding technical specs. It’s a collaborative process that starts with a vision and transforms into tangible, high-performing products ready for the road. For OEMs and Tier-1 suppliers, the ability to move smoothly from concept to detailed design is critical—and that’s where TAAL Tech comes in.

With a strong foundation in automotive engineering services, TAAL Tech supports every stage of product development, offering precision, cost-efficiency, and speed.

Concept Design: Where Innovation Begins

The concept design phase is where vehicle ideas take shape. This stage involves early styling inputs, functional layout exploration, and feasibility assessments. At TAAL Tech, we bring these ideas to life using industry-leading CAD tools and deep engineering expertise.

Our concept design services include:

- Vehicle layout and packaging

- Digital sculpting and Class A surfacing

- Ergonomics and human factor considerations

- Early-stage CAE and CFD support

Whether it’s a new EV model or a combustion engine platform, we provide flexible design engagement models tailored to client needs.

Detailed Design: Turning Ideas into Engineering Reality

Once the concept is locked in, the focus shifts to detailed design—the blueprint for manufacturing. TAAL Tech delivers comprehensive support here, ensuring every nut, bolt, and bracket aligns with the intended performance, cost, and compliance targets.

Our detailed design strengths:

- Body-in-white and closure system design

- Sheet metal and plastic part modeling

- Mechanism design and motion analysis

- Electrical routing and harness design

- Tolerance stack-up and GD&T integration

We integrate seamlessly with client workflows and tools, operating as an extension of their internal teams.

Subsystem Integration Made Smarter

Vehicle systems don’t operate in silos. Our design teams collaborate across disciplines—mechanical, electrical, thermal—to deliver integrated subsystems for:

- HVAC and thermal management

- Chassis and suspension layouts

- Powertrain and drivetrain packaging

- Battery and inverter design (for EVs)

This ensures the vehicle performs as a unified system, not just a collection of parts.

Reducing Design Cycles with Virtual Validation

We minimize design revisions through virtual validation tools and simulation support early in the design process. This approach helps identify and address issues before physical prototyping.

Highlights include:

- Initial crash and durability simulations

- Design for lightweighting

- DFMEA participation

- Feedback integration from CAE teams

Why TAAL Tech?

- Domain expertise across global automotive standards

- Global Capability Center model with hybrid teams

- Tool proficiency in CATIA, NX, Creo, and more

- Transparent communication and responsive delivery

From early ideation to manufacturing-ready designs, TAAL Tech offers a full spectrum of automotive engineering services that help clients get to market faster and smarter.

Looking for engineering support on your next vehicle program?

Let’s connect.