Engineering Intelligent Water Supply Systems for High-Performance Buildings

Water is the one utility that defines both comfort and continuity in any building. From residential towers and hospitals to industrial facilities and data centers, the efficiency of a water supply system determines how reliably a building performs under everyday demand or emergency load. Yet in an era of rising urban density, sustainability codes, and unpredictable resource stress, water system design is no longer about simply delivering flow and pressure. It’s about engineering resilience, intelligence, and long-term efficiency into every pipeline and pump.

At TAAL Tech, we see water supply optimization as a multidisciplinary exercise—where hydraulics, digital modeling, energy management, and sustainability frameworks converge. Our engineers collaborate with developers, consultants, and facility operators to create systems that not only meet code but exceed expectations for efficiency, maintainability, and lifecycle value.

Why Water Supply Design Can’t Be Conventional Anymore

Buildings today operate as interconnected ecosystems. A high-rise may house mixed-use zones—commercial, hospitality, and residential—each with different consumption patterns. Hospitals or data centers demand absolute reliability with redundant pumping and filtration loops. Green buildings pursue LEED or IGBC certification, requiring precise monitoring and water-saving features.

Traditional sizing formulas and manual load assumptions are no longer enough. They often lead to overdesigned networks, wasted energy in pumping, and poor pressure management at endpoints. The modern approach relies on data-driven design, supported by hydraulic simulation, sensor feedback, and digital twin modeling.

For TAAL Tech, this shift is not optional—it’s structural. Our engineers integrate simulation and analytics from the earliest concept stage to ensure every liter delivered serves both performance and sustainability goals.

From Blueprint to Behavior: The Science of Flow Optimization

Optimizing a building’s water supply means balancing three competing parameters—pressure, flow rate, and energy consumption—under dynamic usage conditions. Achieving this requires a systemic view of how water moves, interacts, and recirculates across zones.

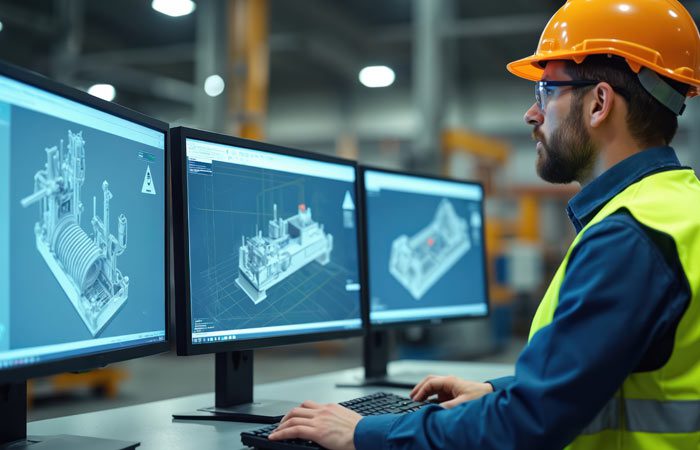

At TAAL Tech, we start with a digital hydraulic model of the network. The model maps out pipe diameters, elevations, losses, and pressure nodes. Using simulation tools such as EPANET or BIM-integrated MEP platforms, our teams evaluate multiple scenarios: peak hour usage, simultaneous demand, firefighting flow overlap, and booster pump response.

This approach allows us to:

- Identify potential low-pressure or stagnation points long before commissioning.

- Right-size pumps and pipe diameters to reduce energy and material costs.

- Validate gravity versus pressurized zone design in high-rise applications.

- Simulate emergency switching between municipal supply and storage tanks.

- Plan efficient hot- and cold-water segregation for better thermal management.

By converting design drawings into living hydraulic systems, we can predict performance under any operating condition—not just on paper but in real-world behavior.

Core Engineering Considerations in Water Supply Optimization

While each project differs in scale and intent, a few design pillars consistently define success.

Pressure zoning and pump selection

In tall buildings, vertical lift and variable demand can easily destabilize pressure. Zoning the network by floor range and using variable frequency drive (VFD) pumps ensures balanced distribution and avoids over-pressurization at lower levels.

Pipe routing and material optimization

Routing should minimize bends and elevation differences to reduce friction loss. TAAL Tech evaluates pipe materials—uPVC, HDPE, copper, stainless steel—based on water chemistry, temperature, and maintenance cycles to strike the right balance between longevity and cost.

Storage and redundancy planning

Tank sizing and placement influence both water quality and pump performance. Designing separate potable and firefighting tanks, integrating break tanks, and ensuring N+1 pump redundancy improves reliability and compliance with NBC and NFPA norms.

Backflow prevention and contamination control

Cross-connection risks rise in mixed-use buildings. Proper use of air gaps, check valves, and dedicated supply lines prevents contamination. Smart sensors and IoT-enabled backflow monitors are now being integrated into digital building management systems.

Energy efficiency and water conservation

Every kWh saved in pumping reduces both operating costs and emissions. Using pressure sensors linked to automated controls allows pumps to run only when required. Greywater recycling, dual plumbing, and rainwater harvesting are engineered as part of a closed sustainability loop, not as add-on features.

The Role of Digitalization

Digital tools have become indispensable in modern water system design. 3D coordination through BIM ensures that plumbing routes integrate seamlessly with structural, HVAC, and electrical layouts, preventing service clashes and rework.

Beyond design, digital twins replicate the real network in operation. Data from flow meters, pressure transmitters, and energy meters feeds into the model to show how the system behaves over time. Engineers and facility managers can visualize trends, detect leaks, or forecast pump maintenance based on real consumption patterns.

TAAL Tech’s teams deploy analytics dashboards that merge hydraulic modeling with IoT telemetry, enabling continuous commissioning rather than a one-time test. It’s an evolution from static design documentation to living digital infrastructure.

Sustainability and Compliance

Global and national standards increasingly demand that water systems balance efficiency with conservation. Codes such as IGBC, LEED, and ECBC now evaluate not just fixture efficiency but also network design, reuse systems, and monitoring.

TAAL Tech aligns each design with the relevant code matrix—from municipal supply standards to OISD and NFPA water demand requirements for industrial or fire protection loops. Our engineers integrate sustainability features such as:

- Demand-based pumping logic controlled through smart PLCs.

- Water-quality sensors that ensure safe reuse cycles.

- Automated leak detection systems to minimize losses.

- Integration with rainwater and STP systems to close the water loop.

For clients, this translates to tangible outcomes—lower energy bills, smaller carbon footprints, and easier certification.

The TAAL Tech Approach: Engineering Efficiency, Reliability, and Intelligence

At TAAL Tech, optimizing building water systems is not about incremental upgrades; it’s about engineering for long-term operational excellence. We approach every project with a system-level view that connects hydraulic science with digital intelligence.

Our methodology combines design precision, domain depth, and execution discipline:

- Simulation-Driven Design: We start with 3D and hydraulic simulations to validate zoning, head loss, and pump logic before drawings reach site.

- Smart Integration: Electrical, mechanical, and plumbing disciplines are synchronized in BIM to avoid service conflicts and support digital facility handover.

- Retrofit Expertise: For brownfield projects, our engineers perform flow audits and sensor-based pressure mapping to redesign legacy systems without major structural changes.

- Lifecycle Data Continuity: Through IoT integration and dashboard analytics, we help operators monitor consumption, detect leaks, and plan preventive maintenance.

- Sustainability Alignment: Every project benchmark is mapped to water-use intensity, helping clients meet internal ESG or green-building targets.

This integrated approach allows TAAL Tech to serve as an engineering partner throughout the asset lifecycle—from concept to commissioning to ongoing performance management.

Applied Engineering Insight

We have multidisciplinary PHE & Fire Fighting design experience—spanning IT campuses, residential towers, data centres, MRT stations, and industrial facilities—our teams implement water supply solutions that are both code-compliant and future-ready. Each design integrates learnings from real-world commissioning and operational feedback to fine-tune efficiency, safety, and maintainability.

Fire and Life Safety Integration

Water supply optimization also extends to fire protection systems. TAAL Tech’s expertise covers the complete fire suppression network—wet and dry risers, sprinkler systems, hydrant layouts, and pump room design—ensuring hydraulic balance and compliance with national and international codes and local fire authority norms. Integrating firefighting and domestic systems within the same hydraulic model helps identify flow interactions and optimize pump operation logic.

Sustainable Design and Green Certification Support

TAAL Tech engineers are experienced in designing PHE systems aligned with LEED and IGBC green building standards. Fixture selection, dual plumbing, and water metering are optimized to meet specific credit requirements under these certification frameworks—contributing directly to water-use reduction and sustainable operations.

Emphasize Digital Coordination Experience

With advanced proficiency in Revit and Navisworks, our engineers deliver coordinated BIM models that integrate plumbing, structural, and architectural data. Clash-free coordination ensures precise service alignment and enables digital facility handover for future maintenance planning

Optional Closing Enhancement

Backed by decades of on-ground design experience and advanced digital tools, TAAL Tech engineers transform traditional water systems into intelligent, resilient infrastructure. Our approach blends hydraulic precision, sustainability, and digital control—building water systems that adapt, conserve, and perform for generations to come.

Building Resilience, One Drop at a Time

Optimizing a building’s water supply system is no longer about pipes and pumps—it’s about foresight, efficiency, and sustainability. In cities where water scarcity and energy costs are growing simultaneously, every design decision carries long-term economic and environmental weight.

For developers and operators, a well-engineered system means fewer disruptions, lower maintenance, and a better occupant experience. For the planet, it means responsible use of a resource that’s becoming increasingly finite.

By combining digital modeling, cross-disciplinary engineering, and sustainability-driven design, TAAL Tech helps organizations build infrastructure that flows smarter, lasts longer, and performs better—today and in the decades ahead.