At TAAL Tech, we help manufacturers transform production efficiency and resilience through cutting-edge Manufacturing Engineering Services. With deep domain expertise and a future-ready approach, we empower businesses across automotive, aerospace, heavy machinery, and industrial sectors to unlock smarter, faster, and leaner operations.

Our comprehensive service portfolio covers every aspect of the manufacturing value chain—from factory layout optimization and digital twin implementation to advanced tooling, CAM programming, and process engineering. We don’t just solve problems; we design scalable, cost-effective, and high-performance solutions tailored to each client’s goals.

TAAL Tech’s cross-disciplinary teams combine traditional manufacturing know-how with emerging technologies like IoT, AI/ML, and data analytics to build agile manufacturing ecosystems. Our solutions reduce cycle time, increase throughput, enhance quality, and ensure better resource utilization—all while lowering operational costs.

Factory Optimization

TAAL Tech’s Factory Optimization services focus on improving the spatial, functional, and operational efficiency of manufacturing facilities. Our approach starts with a detailed analysis of existing factory layouts, material flow, process sequences, and bottlenecks—followed by strategic redesigns that maximize space utilization and minimize non-value-adding activities.

We deploy lean manufacturing principles, value stream mapping, and simulation tools to recommend layout modifications, line balancing solutions, and ergonomic improvements. Our engineers also account for future expansion, multi-product flexibility, and safety compliance during reconfigurations.

From greenfield to brownfield projects, our optimization strategies enable higher throughput, reduced downtime, and smoother workflows across departments. We also ensure alignment between planning, execution, and maintenance functions, improving coordination between shop floor and top floor. The result: a smarter, safer, and more productive factory environment.

Service Areas:

Greenfield & Brownfield Facility Engineering | Virtual Concept Layouts | BIM | Safety & Ergonomic Virtual validation | Process and Discreet Event Simulation

Digital Factory

TAAL Tech enables manufacturers to transition into the digital era through its comprehensive Digital Factory services. We build intelligent, connected ecosystems that provide real-time visibility, predictive insights, and end-to-end control across manufacturing operations.

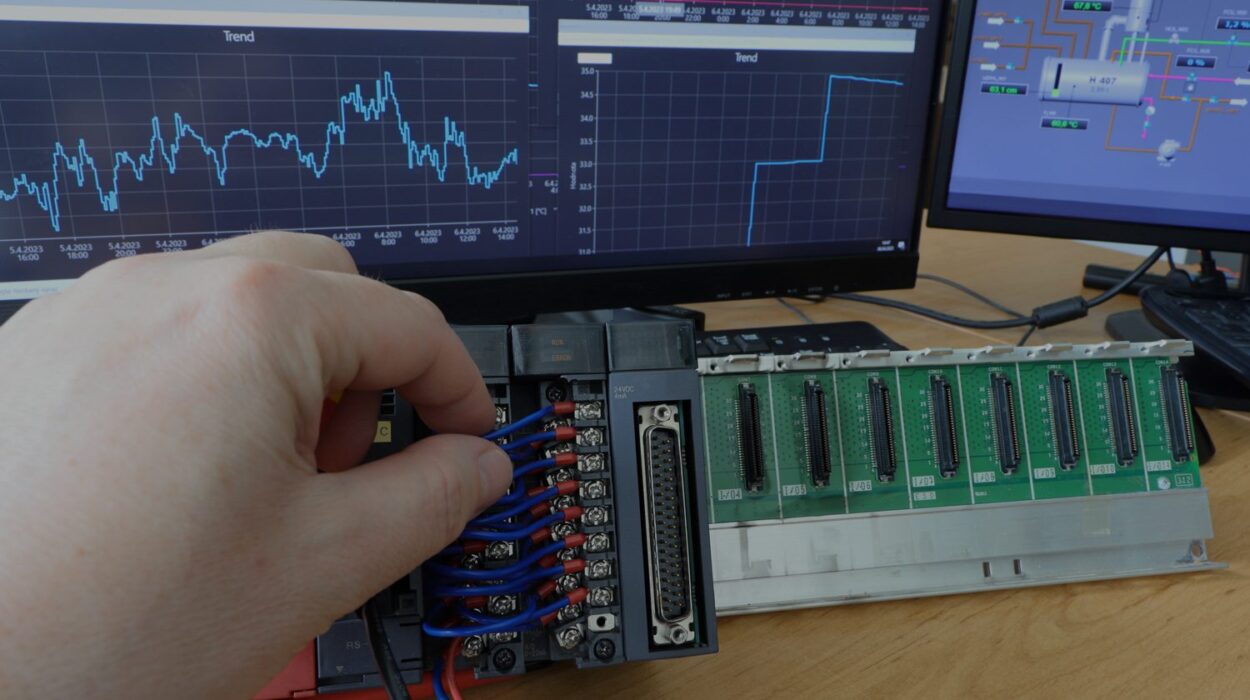

Our solutions include digital twin development, virtual commissioning, IoT integration, and data-driven performance dashboards. We simulate processes to optimize workflows, monitor assets remotely, and implement AI/ML models for predictive maintenance and quality analytics.

By digitizing the plant floor, we help clients reduce unplanned downtime, improve energy efficiency, and increase equipment effectiveness (OEE). Our Digital Factory offering ensures faster decision-making, shorter lead times, and greater agility to respond to market demands.

TAAL Tech’s digital engineering teams work closely with clients to identify automation opportunities, enable traceability, and build cyber-physical systems aligned with Industry 4.0 principles. Whether it’s a single pilot or a full-scale rollout, we turn factories into adaptive, intelligent production hubs.

Service Areas:

IoT Connectivity | AR & VR solutions | Flexible automation | Computer Vision | Intelligent dashboards on Smart screens | Industrial communication Protocol like FieldBus, ProfiBus, HART, IO-Link | HMI’s Design | PLC Programming | Robotic Integration | Cobot Design and Commissioning

CAM & Tooling

Precision manufacturing demands optimized tooling and efficient machining strategies. TAAL Tech’s CAM & Tooling services provide end-to-end support for complex component manufacturing, covering everything from tool design to NC programming and validation.

We offer 2D/3D toolpath generation, post-processor development, and simulation for multi-axis CNC machines across aerospace, automotive, and heavy industries. Our team ensures optimal cutting strategies, reduced cycle times, and minimal tool wear—all without compromising part quality or tolerances.

In tooling, we design and validate jigs, fixtures, gauges, dies, and molds using advanced CAD/CAM platforms like CATIA, NX, Creo, and Mastercam. Our focus on standardization and reusability lowers production costs while maintaining operational consistency.

By integrating CAM automation, digital simulation, and best-in-class tool design practices, TAAL Tech enhances productivity and ensures flawless manufacturability—right from prototyping to mass production.

Service Areas:

Support for 3 & 5 Axis NC programming for Sheet metal, Plate Parts and Extrusion parts | NC Fixture Design and Development | Cycle Time Optimization – key deliverable | Joggle/ Forming/Composite tools design | Assembly & Drilling Jigs | SPM design

Process Engineering

TAAL Tech’s Process Engineering services ensure that your manufacturing operations are optimized, controlled, and continuously improved. We bring deep expertise in developing and refining manufacturing processes that balance speed, quality, and cost-effectiveness.

Our engineers define process parameters, equipment specifications, and operating conditions for both new product introductions (NPI) and continuous improvement initiatives. We apply Six Sigma, PFMEA, control plans, and standard work practices to reduce variability and enhance process reliability.

Whether it’s setting up new assembly lines, scaling up production, or meeting compliance requirements, TAAL Tech supports process validation, capacity analysis, and SOP documentation. We work across domains including discrete, batch, and hybrid manufacturing.

Through robust process design and ongoing optimization, we help clients boost first-pass yield, reduce scrap rates, and streamline workflows—ensuring every product meets performance and quality standards from day one.

Service Areas:

Preparing BOM, PFC, Master Process Sheet, and Operational Technical Data Sheet | Standard operating instructions, SOP’s | Time standards & Line balancing | APQP, PFMEA, Control Plans | Technical Publication: Service Bulletin, AMM,CMM