7 Game-changing Trends in Plant Process Engineering

Plant process engineering is a critical component in the design, operation, and optimization of industrial processes. It ensures efficient production processes, emphasizes safety and quality control, promotes environmental sustainability, contributes to cost-effectiveness, and drives innovation and continuous improvement. With the expertise and skills of plant process engineers, companies can achieve their production goals while maintaining high standards of efficiency, safety, and environmental stewardship. Advancements in technology and changing market demands often drive the evolution of this field.

Here are the top 7 trends in plant process engineering.

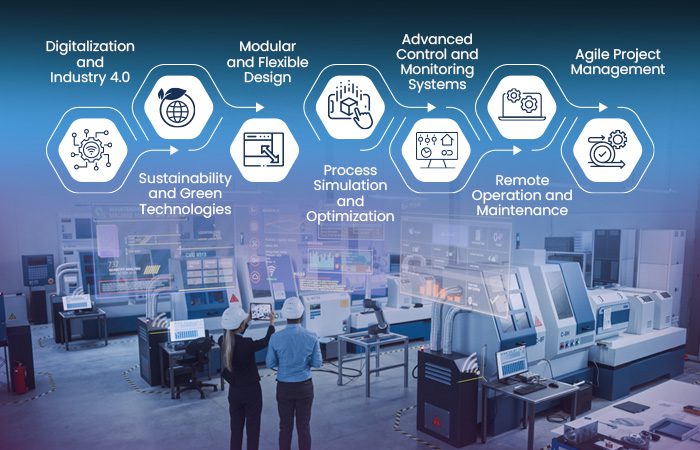

- Digitalization and Industry 4.0

The integration of digital technologies, such as the Internet of Things (IoT), artificial intelligence (AI), data analytics, and automation, is transforming plant process engineering. Smart sensors and connected devices provide real-time data, enabling better monitoring and control of processes. AI algorithms can analyze large datasets to identify trends, optimize operations, and predict maintenance needs.

Using sensors and computer technologies have increased the efficiency and expansion of the process industry. Like it or not, automation technologies will become the most critical technologies that become the growth tool for process and production industries. Looking at the bright side of automation, it not just helps in process and production but also understand the controlled safety features and zero-energy emissions.

- Sustainability and Green Technologies

There is a growing emphasis on sustainable and eco-friendly processes in plant engineering. Technologies such as process intensification, waste heat recovery, carbon capture and utilization, and renewable energy integration are being implemented to reduce environmental impact and improve energy efficiency. The goal is to achieve a more circular and sustainable approach that minimizes waste generation and resource consumption.

- Modular and Flexible Design

Flexible manufacturing processes are gaining popularity as companies strive to accommodate changing consumer demands and shorten time-to-market. Modular design allows for the quick reconfiguration of plant layouts and equipment, enabling easy adaptation to new products, production volumes, or process requirements. This trend requires a deep understanding of process flexibility, automation, and system integration.

- Process Simulation and Optimization

Simulation tools and advanced modeling techniques are increasingly being utilized to optimize and design plant processes. These tools provide insights into process behavior, efficiency, and performance, allowing engineers to test different scenarios virtually before implementation. By optimizing key parameters, such as flow rates, temperatures, and equipment selections, engineers can enhance process efficiency and reduce costs.

- Advanced Control and Monitoring Systems

Real-time process control and monitoring systems help optimize plant performance, ensure product quality, and ensure safety. These systems use advanced algorithms to automatically adjust process variables, detect abnormalities, and predict potential issues. With the integration of AI and machine learning, these systems can continuously learn from data and improve process operation and decision-making capabilities.

- Remote Operation and Maintenance

With the advancements in digital technologies and connectivity, remote operation and maintenance of plant processes are becoming feasible. Remote monitoring and control systems enable experts to access and manage plant operations from remote locations, reducing the need for on-site personnel and improving efficiency. Remote diagnostics and predictive maintenance techniques can detect equipment failures or maintenance needs in advance, minimizing downtime and extending equipment lifespan.

- Agile Project Management

Traditional, sequential approaches to project management are being replaced by agile methodologies in plant process engineering. Agile project management emphasizes collaboration, flexibility, and continuous improvement. It allows for iterative development, faster decision-making, and changes in project scope based on evolving requirements or market conditions.

Thus, plant process engineering is undergoing significant transformations driven by digitalization, sustainability, flexibility, simulation, advanced control systems, remote operations, and agile project management. These trends aim to improve process efficiency, product quality, and sustainability while reducing costs.