Engineering What Moves the World: TAAL Tech’s Mechanical Mastery for Next-Gen Automobiles

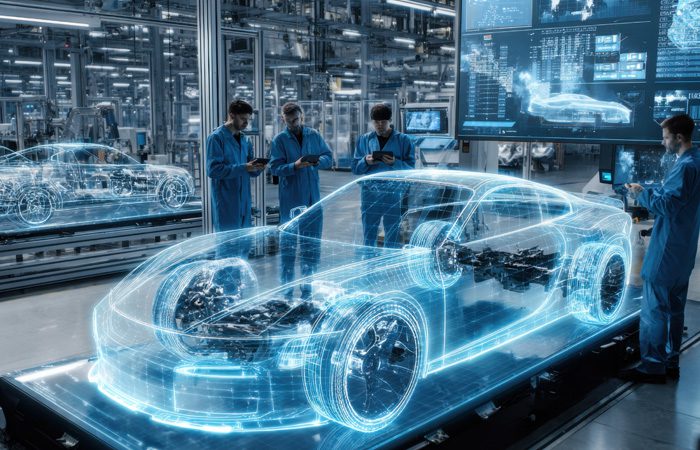

The auto industry is being rebuilt in real time. Emissions norms tighten, vehicles electrify, safety requirements compound, consumers expect quiet refinement and smart features—and all of it must reach the road faster, lighter, and at lower cost. In this landscape, mechanical engineering is not “old school”; it’s the foundation on which every breakthrough stands. At TAAL Tech, we partner with OEMs and Tier-1s to turn complex requirements into manufacturable, compliant, serviceable products—end to end, from concept to SOP and beyond.

This article spotlights how our teams deliver across some of the highest-impact mechanical domains: exhaust systems, heat exchangers, sunroofs, trims, battery mechanisms, injection-moulding tool design, and jigs & fixtures. The common thread is our design-for-everything mindset—DFM/DFA, DFV, NVH, cost, serviceability, and sustainability—executed through a robust digital thread and an agile global delivery model.

Our Engineering Playbook: Rigour, Speed, and Manufacturability

Before diving into specialties, a quick look at how we work:

- Systems-first thinking: We design components as part of the whole vehicle system—validating interfaces, packaging, thermal paths, loads, and regulations concurrently.

- Model-based, simulation-led: We front-load decisions with CAD, CAE, and CFD, reducing late-stage changes. Digital prototypes let us explore more options, faster.

- Production readiness by design: Tooling, tolerances, materials, and assembly are baked in from Day 1. We align with IATF 16949 processes, PPAP, APQP, and relevant SAE/ECE/FMVSS standards.

- Hybrid global delivery: Onsite discovery + offshore execution gives speed and scale. Ramp-up/ramp-down models align engineering capacity with your program cadence.

- Cost and sustainability: VAVE workshops, lightweight strategies, and recycled/low-impact materials help meet both the business case and ESG goals.

Exhaust Systems: Efficiency, Acoustics, and Durability in One Package

Exhaust engineering is a balancing act: emissions efficiency, acoustics, backpressure, packaging, and thermal durability must harmonize under brutal duty cycles. TAAL Tech’s exhaust teams specialize in:

- Architecture & packaging: Routing for ground clearance, thermal shielding, and crash zones; bracket and hanger strategies to control movement and avoid rattle.

- Aftertreatment integration: DOC/DPF/SCR layouts for compliance across markets; substrate sizing, cone geometry, and canning design to prevent mat erosion and thermal shock.

- Muffler & NVH tuning: Perforation patterns, baffle geometry, and expansion volumes; predictive models to hit pass-by noise targets without sacrificing performance.

- Thermal management: CFD for skin temperature control, shield design, and catalyst light-off; material selection for high-temperature oxidation and corrosion resistance.

- Durability & validation: Fatigue analysis for welds and brackets, stone-impact protection, water-ingress condensation strategies, and salt spray considerations.

For ICE and hybrid vehicles in growth markets, these optimizations deliver compliance and refinement while containing mass and cost. For performance programs, we bring track-grade durability and tonal character tuning without regulatory surprises.

Heat Exchangers: Thermal Systems That Make or Break Efficiency

From ICE charge-air coolers to EV battery chillers, thermal performance governs range, longevity, and drivability. We engineer:

- Radiators & condensers: Core sizing, fin density, and header geometry tuned via 1D/3D co-simulation to balance pressure drop and heat rejection; tank designs for burst and fatigue.

- Intercoolers (air-to-air & air-to-liquid): End-tank CFD to eliminate recirculation zones, improve flow uniformity, and trim turbo lag; packaging for crash and stone-impact robustness.

- EGR coolers & heater cores: Fouling-resistant pathways, brazing-friendly materials, and thermal fatigue mitigation for long life under transient cycles.

- EV thermal modules: Integrated battery chiller loops, plate heat exchangers, and smart valve manifolds; coupling cabin HVAC with battery conditioning for optimal energy use.

- System integration: Ducting, seals, and shrouds; fan curves and control strategies; under-hood pressure zones and aero-thermal synergy.

Our teams focus on whole-vehicle thermal balance—aligning cooling capacity with aero targets, grille shutters, and climate variants to avoid over-engineering while safeguarding hot-soak performance.

Sunroofs: Precision Kinematics, Leak-Free Lifetime

Few features delight customers like a smooth, quiet, leak-free sunroof. Fewer still are as unforgiving to engineer. TAAL Tech delivers:

- Mechanism design: Rail and carriage kinematics, cable routing, motor/gearbox selection, anti-pinch strategies, and structural integration for rollover and roof crush criteria.

- Sealing & water management: Primary/secondary seals, drain channel design, and robust hose routing with tolerance stack-up control to prevent NVH squeaks and water leakage.

- Glazing & frame: Material selection (tempered/laminated), bonding strategies, and corrosion-resistant frame design; thermal expansion management to avoid binding.

- Validation: Rattle & shake, water-spray & flood tests, thermal cycling, icing, dust ingress, and life testing with environmental profiles by market.

We combine analytical models with accelerated life rigs to qualify kinematics and sealing early—saving time and warranty cost later.

Interior & Exterior Trims: Fit-Finish that Defines the Brand

Trims translate brand promise into what customers see and touch. We engineer trims that install smoothly, meet safety standards, and age gracefully.

- Interior trims: Door, IP, console, pillar, and headliner panels with lightweight ribbing, living hinges, and clip strategies that allow fast, damage-free assembly. NVH absorption and buzz/squeak/rattle mitigation.

- Exterior trims: Fascia, grilles, sill and wheel arch claddings, appliqués, and aero features designed for paint, plating, or molded-in-color processes; stone-chip and UV resistance.

- Materials & sustainability: PP/ABS, PC-ABS, TPO, and bio-based blends; natural-fiber reinforcement; recycled content options with no compromise on dimensional stability.

- Tolerance & GD&T excellence: Robust datum strategies and locator plans; CAE-informed wall thickness and rib patterns to minimize sink, warpage, and read-through.

Our trim work is tightly coupled with manufacturing and tooling—we resolve sink marks, weld lines, and flow issues in simulation so production ramps with confidence.

Battery Mechanisms & Enclosures: Safety, Serviceability, and Thermal Integrity

Electrification shifts mechanical focus from pistons to packs. We help OEMs reduce risk and time-to-market with battery-mechanical expertise:

- Pack structure & enclosure: IP-rated housings, crash load paths, venting strategies, and seal architectures; corrosion-resistant designs for road salt and debris.

- Module & cell packaging: Tolerance-aware interfaces, compression systems for prismatic/pouch cells, busbar layouts, and thermal isolation strategies.

- Service & access mechanisms: Fasteners, latches, lift points, and under-vehicle access designed for safe removal and repair, minimizing downtime and labor.

- Thermal management: Cold plates, gap fillers, and manifold routing; CFD to ensure temperature uniformity and mitigate hotspots during fast charging and peak loads.

- Safety & compliance support: Integration paths for BDU, fusing, and fire mitigation features; design inputs aligned with global regulatory and OEM standards.

We design battery systems with a field-service mindset, reducing total cost of ownership while ensuring structural integrity and thermal safety across life.

Injection-Moulding Tool Design: Where Design Meets Reality

Great plastic parts are born in great tools. TAAL Tech’s tooling engineers collaborate early to ensure parts are moldable, repeatable, and economical:

- Tool architecture: Single/multi-cavity, family tools, hot runner vs. cold runner, and quick-change inserts for program flexibility.

- Cooling & cycle time: Conformal and conventional cooling strategies validated in simulation to reduce hotspots and warpage while minimizing cycle time.

- Gating & venting: Gate types and locations optimized for flow, aesthetics, and weld-line control; precise venting to avoid burn marks or short shots.

- Steel selection & coatings: Tool steel grades and surface treatments chosen for abrasion resistance, corrosion, and polishability (Class A surfaces).

- Mold-flow integration: Fill, pack, cool, and warp analyses feed back to part design—trimming mass, reducing defects, and protecting cosmetics.

By closing the loop between product and tooling, we cut iterations and de-risk PPAP—so SOP is a non-event.

Jigs & Fixtures: Precision That Scales to Production

From BIW welding fixtures to end-of-line gauges, our tooling turns design intent into repeatable manufacturing reality:

- Welding & assembly fixtures: Locating schemes, clamps, and datum strategies that control variation; ergonomic design for operator safety; options for semi/fully automated stations.

- Checking fixtures & gauges: Attribute and variable gauges with CMM correlation; lightweight, rigid structures for shop-floor durability and easy handling.

- Modularity & maintainability: Quick-change nests, standardized components, and intuitive adjustment mechanisms to reduce downtime.

- Process integration: PFMEA inputs, cycle-time studies, and poka-yoke features; digital twins for reach, clearance, and sequence validation.

Our fixtures are designed for precision and uptime, cutting scrap and rework while enabling high OEE across shifts and model variants.

How We De-Risk Programs: A Typical Collaboration Model

- Definition & decomposition: Capture requirements, regulations, and KPIs (mass, cost, NVH, thermal, durability). Build the V&V plan and DVP&R at kickoff.

- Rapid concepting: Parallel concept streams with quick CAD/CAE loops and material/process trade-offs.

- Virtual validation: CAE/CFD for loads, vibration, fatigue, flow, thermal; tolerance analysis; mold-flow and assembly simulation. Early supplier/tooling input.

- Prototype & test: Functional prototypes, rig tests, and correlation to models. Iterate fast via concurrent design and tool changes.

- Industrialization: Tooling, fixtures, PFMEA, control plans, and PPAP documentation; run@rate and launch support.

- Sustain & improve: Field-data feedback, VAVE, and running changes; platform carry-over strategies for future models.

This approach compresses timelines, increases first-time-right rates, and creates a traceable digital thread from requirement to release.

Why TAAL Tech

- Domain depth across systems: From exhaust acoustics to battery thermal plates, we bring specialists who speak your system’s language.

- Toolchain fluency: Proficiency across major CAD/PLM/CAE/CFD/mold-flow ecosystems—so we plug into your environment without friction.

- Global, agile capacity: Ramp teams up or down as program phases evolve; onsite/offshore blending for responsiveness and cost efficiency.

- Compliance confidence: We design and document to industry standards and regional regulations, reducing homologation risk.

- Value without compromise: VAVE that protects customer-perceived quality while meeting aggressive cost targets.

Let’s build what’s next, together. Whether you’re optimizing an aftertreatment line for a hybrid SUV, industrializing a new sunroof mechanism, or launching an EV battery pack for global markets, TAAL Tech brings the mechanical engineering depth, digital tooling, and manufacturing pragmatism to deliver—on time, at quality, and at scale. Reach out to explore how our teams can accelerate your program from concept to confident launch.