BIM Execution for Multi-Site Rollout Projects: Retail, Warehouses, and QSR Chains

When you’re rolling out 20, 200, or 1,000 locations of the same brand, the challenge isn’t “Can we design this store?” — it’s “Can we repeat this design reliably, at speed, across different footprints, cities, and codes without losing control?”

BIM has already moved into the mainstream: global BIM market revenue is projected to grow from around USD 8.5 billion in 2024 to more than USD 23 billion by 2033, and BIM-in-construction alone is forecast to triple in value over the next decade. Surveys show that in many mature markets, well over two-thirds of architects, engineers and contractors use BIM on more than half their projects.

But there’s a difference between using BIM on projects and industrializing BIM for multi-site rollouts. The latter is where standardized workflows, content libraries, and common data environments turn BIM into a genuine rollout engine.

Why Multi-Site Rollouts Need a Different BIM Strategy

Retail, healthcare, warehouse, and QSR rollouts live under three permanent pressures:

-

- Speed to open – Every week of delay in opening a store, clinic, or outlet translates into lost revenue and sunk marketing spend.

- Brand consistency at scale – Lighting, finishes, fixtures, signage, and customer flow have to feel “on brand” whether the site is in Chicago, Rotterdam, or Dallas.

- Local variability – No two shells are identical: structural grids, landlord MEP provisions, local codes, and site constraints vary dramatically.

Traditional “project-by-project” BIM can absolutely produce drawings, but it often leads to:

-

- Different model standards per region or architect

- Teams re-drawing the same details and layouts from scratch

- Limited reuse of families and assemblies

- Poor visibility at program level across dozens or hundreds of sites

By contrast, a programmatic BIM approach starts from centralized standards, reusable content, and repeatable workflows, and then scales those across sites through a common data environment like Autodesk Construction Cloud (ACC).

In one North American QSR program, TAAL Tech supported a design partner in rolling out more than 60 outlets by creating a “prototype model” with parametric seating, counter, and kitchen modules. Each new shell was adapted in days, not weeks, because the core logic, content, and documentation workflows were already standardized.

From One-Off Models to Reusable Families and Layout Kits

For repeated builds, the real value doesn’t come from a gorgeous one-off BIM model. It comes from industrialized building blocks that can be reused and adapted.

- Brand-standard content libraries

-

- Parametric Revit families for fixtures, signage, menu boards, shelving, POS counters, kitchen and back-of-house equipment

- Materials tied to global spec codes and cost codes

- Standard detail views and sheets for typical junctions, soffits, MEP drops, and service zones

- Layout “kits of parts”

-

- Front-of-house zones (entry, queuing, merchandising walls, self-checkout, seating islands) created as repeatable assemblies

- Back-of-house modules (prep area, cold storage, dry storage, staff amenities, mechanical rooms) that can be combined and mirrored

- Parametric rules for adaptation

-

- Rules for minimum clearances, circulation widths, sightlines, and servicing routes

- Dynamo or scripting routines to rapidly re-fit prototype layouts into new shells

- Fit-out-ready models

-

- Models coordinated enough (architecture + MEP + key coordination zones) that they can go straight to CDs and shop drawings with minimal rework for each site.

In a European convenience retail rollout, TAAL Tech helped the architect-of-record establish a content library of branded fixtures and signage plus three core “store typologies.” New shells started from the closest typology and then adjusted parameters instead of redrawing everything. Design cycle time per store dropped by weeks, and visual consistency across countries became much easier to enforce.

ACC-Driven Workflows: One Source of Truth for 20–1000 Sites

Beyond a handful of sites, file-based BIM coordination simply doesn’t scale. Emailing models, juggling FTP links, or relying on inconsistent file servers makes it almost impossible to ensure that:

-

- Every site is using the latest content and standards

- Issues, RFIs, and design decisions are traceable across the program

- Multiple local architects and engineers stay aligned to common rules

Platforms like Autodesk Construction Cloud (ACC) and BIM Collaborate/BIM Collaborate Pro provide a cloud-based common data environment that solves this with:

-

- Centralized model hosting, version control, and permissions

- Coordination spaces with clash detection and issue tracking

- Role-based access for owners, PMs, architects, engineers, contractors, and BIM partners

- Repeatable templates for folders, naming, and review workflows that can be cloned across projects

For multi-site rollouts, that translates into:

-

- Standard project templates – every new site starts with identical folder structures, naming conventions, and approvals.

- Central content libraries – brand fixtures and detail libraries are updated once and immediately used by every active site.

- Program-level dashboards – PMs see which sites are at concept, DD, CD, tender, and as-built, and can track clashes, open issues, and review status across the entire portfolio.

Retail, Warehouses, and QSR: Different Typologies, Same BIM Logic

On the surface, a QSR fit-out, a small clinic, and a last-mile warehouse have little in common. From a BIM rollout perspective, they share the same pattern: repeatable typologies with local variation.

Retail & QSR fit-outs

-

- Emphasis on brand experience and customer journey

- Tight construction windows in live malls or dense urban locations

- Heavy coordination of signage, lighting, AV, and dense MEP in restrictive ceiling zones

Standardized BIM libraries and zone-based layouts ensure that lighting levels, fixture spacing, accessibility clearances, and branding elements are consistent across dozens of sites, while clashes are resolved in the model instead of on the night before opening.

Clinics and small healthcare

-

- More stringent codes and clinical adjacencies

- Highly repeatable room types: exam rooms, procedure rooms, labs, waiting areas

- Strict requirements for clean/dirty flows and MEP provisions

Here, BIM encodes standard room modules and MEP zones so that new shells can be adapted without compromising compliance.

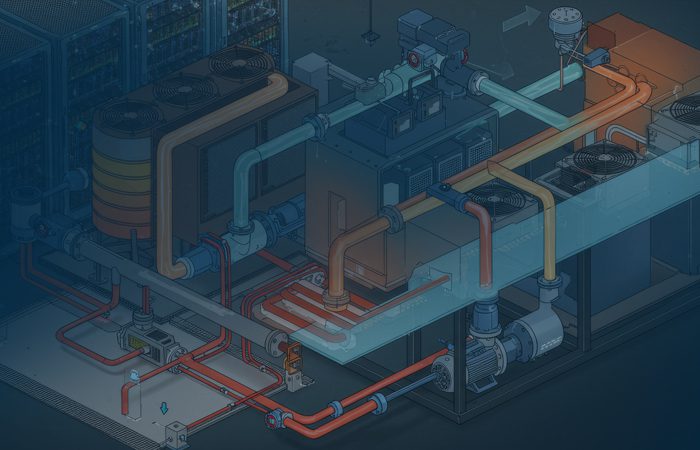

Warehouses & logistics hubs

-

- Large volumes, repetitive racking and dock modules

- Critical interfaces between structure, sprinklers, racking, automation, and yards

Standard racking, dock door, battery charging and mezzanine modules inside BIM allow rollouts to be scaled quickly while maintaining local fire, egress, and seismic compliance.

Measurable Benefits: From Clash Reduction to Cost and Schedule Gains

Across multiple studies, BIM has been shown to dramatically cut errors and rework:

-

- 50–60% reduction in design errors

- 40–50% reduction in rework costs

- 40% fewer clashes, and significantly fewer unbudgeted changes and RFIs

Industry data also show that rework can account for anywhere from 4–12% to nearly 30% of total project cost, largely driven by design errors and coordination failures — exactly the problems BIM is designed to address through better clash detection and coordinated documentation.

When you apply BIM in a standardized, programmatic way to multi-site rollouts, those benefits compound:

-

- Higher design consistency across markets and consultant teams

- Shorter design cycles per site, because teams aren’t reinventing layouts and details

- Lower on-site rework and fewer RFIs, thanks to standard details and coordinated models

- Faster onboarding of new local partners who plug into an established BIM playbook

- Program-level visibility into progress, risk, and quality using ACC dashboards

The result is not just cleaner models. It’s more predictable openings, tighter CAPEX control, and fewer last-minute surprises across the entire rollout.

TAAL Tech’s POV: BIM Production Partner for 20–1000 Site Rollouts

In large rollouts, LJC/PMDG/WMC/AO-type firms (design-led practices and program managers) rarely want to build a giant BIM production engine internally. They want a partner who can industrialize production while they focus on client strategy, entitlements, and design leadership.

This is where TAAL Tech slots in as a BIM production and execution partner:

-

- Centralized, brand-specific content libraries

TAAL Tech builds and maintains Revit families, detail libraries, view templates, and room/zone types that encode the brand’s design DNA.

-

- ACC-driven, multi-project frameworks

TAAL Tech helps structure ACC/BIM Collaborate environments with standard folder templates, permissions, issue workflows, and coordination spaces, so every new site is “plug-and-play” from a BIM standpoint.

-

- Standardized modelling & documentation workflows

From prototype through CDs and as-builts, consistent naming conventions, sheet sets, and QA/QC checks are applied across all sites.

-

- Scalable production capacity

Because content and workflows are standardized, TAAL Tech can ramp from a pilot of 20–30 sites to 200+ sites per year while maintaining quality and predictable schedules.

In one international coffee chain program, TAAL Tech ran a centralized BIM cell. Local architects handled entitlements and shell coordination; TAAL Tech produced and coordinated interior models, managed the content library, and handled documentation for each site. Lead designers focused on brand and customer experience; TAAL Tech ensured the rollouts stayed on BIM rails.

Closing: Turning BIM into a Rollout Engine

BIM on a single flagship store or warehouse is useful. BIM as a repeatable platform for hundreds of sites is a competitive advantage.

For retail, warehouse, healthcare, and QSR brands, the leaders will be those who can:

-

- Design strong, branded prototypes

- Encode them as reusable BIM logic and content

- Execute them through standardized, cloud-based workflows across markets

Surveys of BIM users consistently show high ROI and better project outcomes compared to non-BIM approaches — from fewer change orders to better schedule performance and cost predictability.

If you’re a program manager, architect-of-record, or GC orchestrating multi-site rollouts, it may be time to stop treating BIM as “just a deliverable” and start using it as a rollout engine.

TAAL Tech partners with firms like LJC, PMDG, WMC, AO-type companies as the BIM execution backbone — building content libraries, structuring ACC environments, and delivering consistent, fit-out-ready models from site 1 to site 1000.