How 3D Modeling is Transforming Plant Design Engineering

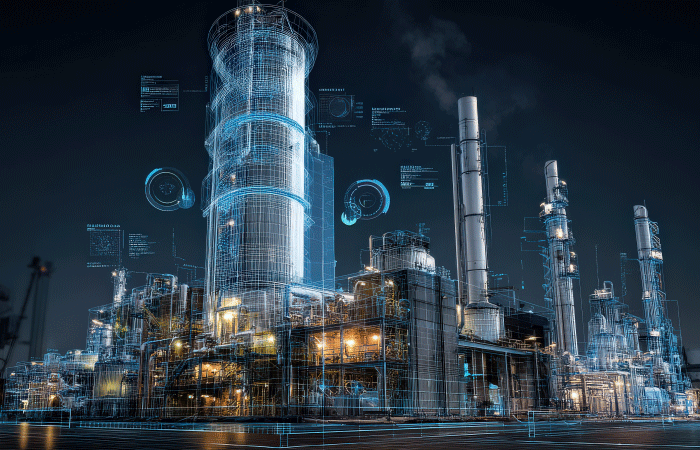

The field of plant design engineering has entered a new era, powered by the rapid adoption of digital tools and advanced visualization techniques. At the center of this transformation lies 3D modeling in plant engineering, which is enabling engineers and designers to create smarter, safer, and more cost-effective plants. From concept to operations, 3D plant design is revolutionizing the way industrial facilities are conceived, planned, and executed.

The Shift to Digital Plant Design

For decades, plant layouts and designs were created through 2D drawings and static documents. While effective to a degree, these methods often resulted in inefficiencies, errors, and costly revisions during construction. With the rise of 3D plant modeling software, the industry has shifted toward digital plant design, offering stakeholders dynamic, data-rich environments that provide unparalleled accuracy.

By adopting engineering design services built around 3D tools, companies gain a competitive advantage in delivering projects that are both efficient and sustainable. The transition from traditional drafting to 3D engineering design solutions ensures that every pipe, structure, and piece of equipment is modeled with precision and context.

Benefits of 3D Modeling in Plant Design

The benefits of 3D modeling in plant design extend across the entire project lifecycle:

- Improved Accuracy: 3D models reduce human errors and ensure accurate alignment between disciplines.

- Clash Detection in Plant Design: Engineers can identify and resolve conflicts between piping, structural, and electrical systems before construction begins.

- Enhanced Visualization: Stakeholders can better understand the plant’s layout through immersive design visualization for industrial plants.

- Reduced Costs: By preventing rework and delays, 3D modeling contributes to reducing CapEx and OpEx with 3D modeling.

- Collaboration: Teams across geographies can work on shared 3D models, improving coordination and communication.

These factors make 3D modeling not just a design tool but a strategic enabler of smarter decision-making.

The Role of 3D Modeling in Plant Design Services

Modern plant design services are increasingly built around advanced 3D workflows. Whether it is front-end engineering design (FEED), detailed engineering design, or operations planning, 3D models provide a single source of truth for all stakeholders.

- FEED: In early design phases, 3D models help teams evaluate different layout options, space utilization, and equipment placement. This provides clarity for cost estimation and project feasibility.

- Detailed Engineering Design: During execution, 3D models guide precise fabrication and installation, ensuring consistency between design and construction.

- Operations and Maintenance: The creation of a digital twin in plant engineering extends the value of 3D models into the operations phase, providing insights for maintenance planning, lifecycle cost analysis, and upgrades.

This integration demonstrates the crucial role of 3D modeling in plant design services, where digital continuity drives both efficiency and quality.

Applications Across Industries

The adoption of 3D plant design is not limited to one sector. It is widely applied across oil and gas, power, chemical, and pharmaceutical industries.

- 3D Modeling for Oil and Gas Plant Design: Complex refineries and petrochemical facilities benefit from accurate piping layouts, safety simulations, and clash-free designs.

- Industrial Plant Design: Manufacturing plants rely on 3D models for space optimization and efficient equipment placement.

- 3D Modeling for Sustainable Plant Design: By simulating energy performance and emissions, 3D models play a vital role in designing environmentally responsible facilities.

This versatility makes smart plant design engineering a cornerstone of modern industrial projects.

How 3D Modeling Improves Plant Engineering

The question of how 3D modeling improves plant engineering can be answered through tangible project outcomes:

- Faster design approvals due to improved visualization

- Early detection of safety and compliance issues

- Shorter construction timelines thanks to prefabrication supported by precise 3D models

- Reduced material waste and better resource allocation

These improvements demonstrate why the advantages of using 3D plant modeling software are now widely recognized by AEC and EPC companies.

Reducing Costs Through 3D Plant Design

Cost efficiency remains one of the biggest drivers of 3D adoption. By providing accurate layouts and enabling clash detection in plant design, projects avoid expensive rework during construction. Furthermore, the ability to simulate operational scenarios contributes to reducing CapEx and OpEx with 3D modeling, as facilities operate more efficiently and require fewer unplanned interventions.

In a highly competitive market, this financial advantage ensures that companies adopting 3D engineering design solutions stay ahead.

The Future of Plant Engineering with 3D Modeling

Looking ahead, the future of plant engineering with 3D modeling is tied closely to other digital innovations. The integration of IoT data, AI-driven analytics, and digital twins will make 3D models even more intelligent and valuable. Facilities will not only be designed digitally but also monitored and optimized in real time throughout their lifecycle.

This evolution highlights the growing role of 3D modeling in enabling smarter, more connected, and sustainable industrial operations. Engineering service providers like TAAL Tech are already supporting this transformation by helping clients adopt advanced CAD for plant engineering and digital-first practices that drive measurable results.

Final Thoughts

The impact of 3D modeling in plant engineering is undeniable. By enabling digital plant design, streamlining workflows, and ensuring cost and time efficiency, 3D modeling has become a cornerstone of modern plant design engineering. From front-end engineering design to detailed engineering design, and from industrial plant design to sustainable plant facilities, the technology has redefined how projects are delivered.

As industries push toward digital transformation, the adoption of 3D plant design will only accelerate. With capabilities like digital twin in plant engineering, real-time monitoring, and smart plant design engineering, the path forward is clear: 3D modeling is not just transforming plant design—it is shaping the future of industrial engineering.