Dynamic Equipment Foundations

In the realm of structural engineering for industrial facilities, including hydrocarbon, chemical, power, and water treatment plants, several key tasks and considerations come into play.

TAAL Tech specializes in delivering cutting-edge plant structural engineering services, embodying a commitment to excellence and innovation. With a robust team of seasoned engineers, we offer comprehensive solutions tailored to the unique needs of industrial plants. Our expertise encompasses structural design, analysis, and optimization, ensuring the integrity and efficiency of plant structures. Utilizing advanced technologies and industry-best practices, we deliver cost-effective solutions that enhance safety, durability, and performance. From conceptualization to execution, TAAL Tech’s services span a wide spectrum, including retrofitting, expansion, and maintenance projects. Our client-centric approach prioritizes seamless collaboration and timely delivery, making us a trusted partner in the dynamic landscape of plant engineering.

Conducting dynamic analysis to determine the loads and vibrations generated by rotating equipment (e.g., pumps, compressors) and establish design criteria. Designing robust foundations that mitigate vibrations and ensure stability, considering factors like soil conditions, equipment loads, and operational frequencies.

Performing Geotechnical Analysis to understand soil conditions and assess bearing capacity. Choosing between deep and shallow foundations based on soil properties, loads, and structural requirements.

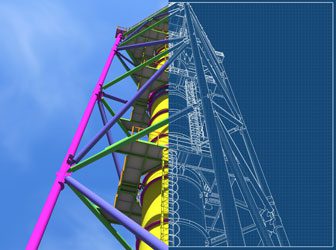

Conducting structural analyses to determine the loads on process towers, considering equipment loads, wind forces, seismic loads, and temperature effects. Use 3D modelling and clash detection tools to identify and resolve potential clashes between structural elements and other systems. Material selection for the construction of process towers based on structural and environmental considerations.

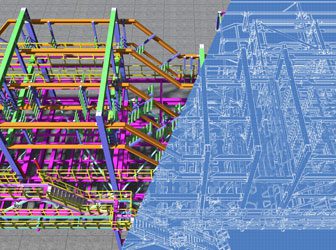

Performing Load Analysis from piping systems, including dead loads, live loads, and dynamic loads. Designing pipe racks and supports to accommodate thermal expansion, contraction, and vibration while ensuring structural integrity. Ensuring material used in pipe racks and supports are compatible with the conveyed substances and environmental conditions.

Safe and accessible access Platform Design for equipment maintenance, inspection, and operation. Stair, Ladder and Handrails Designing that comply with safety regulations and provide easy access for personnel. Integrating safety features such as guardrails and fall protection systems into platform design.

Performing seismic analysis to determine the seismic forces on structures and foundations. Undertake Reinforcement Designing to resist seismic forces, including the use of seismic reinforcement detailing.

Implementing fireproofing measures for structural elements exposed to high temperatures during a fire. Designing structures to maintain integrity under fire conditions and support firefighting efforts.

Implementing quality control measures during construction to ensure compliance with design specifications. Designing structures with a focus on durability, considering factors such as corrosion protection and maintenance requirements. Ensuring that structural designs comply with relevant building codes, industry standards, and regulatory requirements.

Internal collaboration with process engineering team to ensure alignment between process design and equipment layout. Engaging with client to understand specific layout requirements and preferences and feedback to meet their operational needs.

Aspen HYSYS

CADWorx

AutoCAD Plant 3D

E3D

SmartPlant-PID

AutoCAD

CAESAR II

AutoPIPE

STAAD.Pro

AutoPLANT

Tekla

ETAP