Pressure Vessels

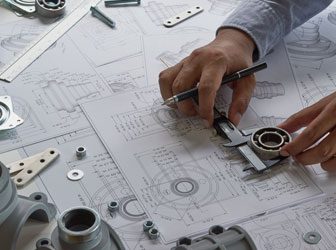

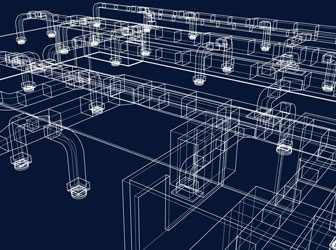

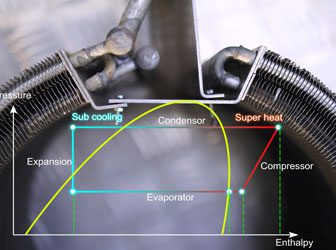

In mechanical engineering for industrial facilities, various aspects are considered to ensure the integrity, safety, and efficient operation of equipment and systems. TAAL Tech stands as a premier provider of plant mechanical engineering services, offering a comprehensive suite of solutions that optimize machinery, systems, and processes within industrial plants. Our team of skilled mechanical engineers excels in conceptualizing, designing, and implementing innovative solutions tailored to the specific needs of each client. From equipment selection and installation to maintenance strategies, TAAL Tech prioritizes efficiency, reliability, and compliance with industry standards. With a focus on cutting-edge technologies, we drive advancements in mechanical systems to enhance performance and longevity. Performing design calculations and analysis for pressure vessels to ensure they can safely contain and withstand the internal pressures and loads. Ensuring compliance with applicable pressure vessel codes and standards (e.g., ASME Boiler and Pressure Vessel Code). Conducting Dynamic and Static stress analysis for piping systems to ensure they can withstand static and dynamic loads. Ensuring compliance with piping codes and standards (e.g., ASME B31.3) to guarantee the integrity of the piping systems. Sizing and Selection of pressure relief devices (PRVs and PSVs) based on the calculated relief loads. Analysis of relief scenarios to ensure proper sizing and location of relief devices for overpressure protection. Designing tanks for storage of liquids or gases, considering factors such as material selection, structural integrity, and environmental conditions. Ensuring compliance with industry standards such as API 650 for atmospheric storage tanks or API 620 for low-pressure storage tanks. Developing detailed equipment specifications for various mechanical components, including pumps, compressors, heat exchangers, and rotating equipment. Collaborating with equipment vendors to ensure that specified equipment meets project requirements. Designing pipe supports and hangers to ensure proper alignment, weight distribution, and support for piping systems. Performing stress analysis for hangers to ensure they can withstand the loads imposed by the supported pipes. Performing thermal analysis for heat exchangers to ensure effective heat transfer. Designing heat exchangers to withstand thermal expansion, pressure, and other mechanical loads. Conducting rotord ynamics analysis for rotating equipment like pumps and compressors to ensure stability and prevent excessive vibrations. Specify and ensure proper balancing of rotating equipment to minimize vibrations and ensure longevity. Developing inspection plans for mechanical components to ensure ongoing integrity and compliance with regulatory requirements. Performing fitness-for-service assessments to evaluate the condition of existing equipment and determine if it meets operational requirements. Collaborating with instrumentation and control engineers to ensure seamless integration of mechanical components with control systems. Integrating Safety Instrumented Systems for critical mechanical components. Aspen HYSYS CADWorx AutoCAD Plant 3D E3D SmartPlant-PID AutoCAD CAESAR II AutoPIPE STAAD.Pro AutoPLANT Tekla ETAP Experience efficiency in every component

Pressure Vessels

Piping Stress Analysis

Pressure Relief Valves (PRV) and Pressure Safety Valves (PSV) Analysis

Tanks

Equipment Specifications

Hanger Design

Heat Exchanger Design

Rotating Equipment

Mechanical Integrity Programs

Instrumentation and Control Interface

Technologies

Why TAAL Tech?

Secure better project outcomes & improved ROI with TAAL Tech’s digitized engineering support. Get started now!